At DSC Lab, in addition to reverse engineering, we are actively involved in developing products entirely from scratch. These projects are among the most interesting for us, as they combine engineering logic, industrial design, and real-world manufacturing constraints. Increasingly, we work with clients who have a clear product idea but lack the means to turn it into a physical, manufacturable object. In such cases, our role is to transform a concept into a functional and production-ready product.

Product Concept and Core Engineering Requirements

In this case, the client was a software engineer with solid hardware knowledge and a concept for a compact electronic device. The idea was a product with the form factor of a small radio transceiver—roughly the size of a cigarette box. The client provided the main electronic components: PCBs, battery, antenna, ports, and a display.

The primary challenge was integrating all these elements into an enclosure with minimal overall dimensions, while still ensuring proper cooling, ease of assembly, and sufficient structural strength.

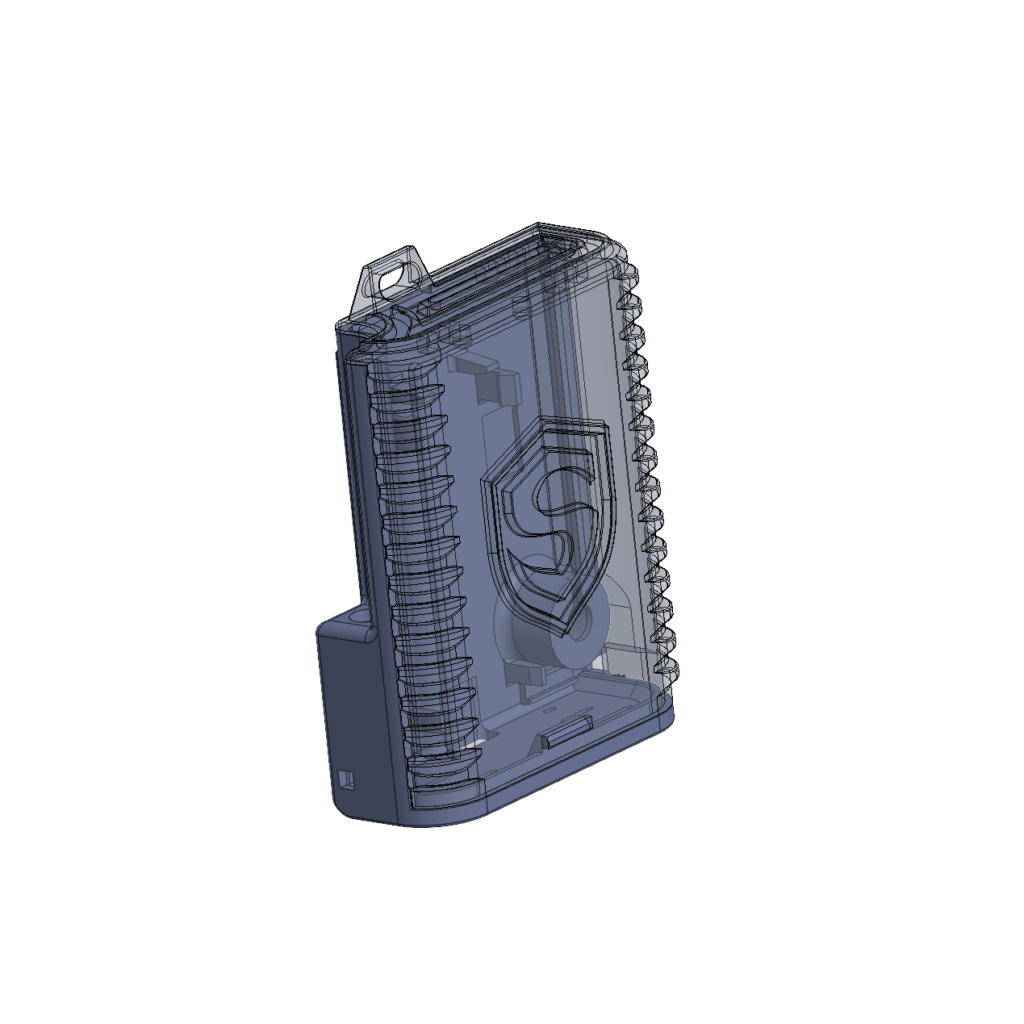

These requirements imposed significant design constraints. The internal space was extremely limited, and each component required a precisely defined position and mounting method. An additional requirement was easy assembly and disassembly for servicing. Due to confidentiality considerations, we cannot disclose all internal details of the product, but the final enclosure can be seen in the presented visuals. From the outset, the enclosure was intended for 3D printing, and the entire design had to be adapted accordingly.

Technology Selection and Design for Additive Manufacturing

Such a product could theoretically be manufactured using injection molding, but this approach is economically viable only for production runs in the thousands. Tooling costs are high, and lead times are long. For short production series—tens or hundreds of units—additive manufacturing is a far more cost-effective solution.

Several 3D printing technologies are suitable for this type of enclosure. SLS using PA12 offers excellent strength and geometric freedom but comes at a higher cost and requires post-processing. Photopolymer resin printing delivers outstanding detail and smooth surface finish, but the parts tend to be more brittle and less resistant to mechanical stress. For enclosure applications, the most commonly used technology remains FDM, which provides a solid balance between cost, durability, and visual quality.

For this project, we selected FDM 3D printing. This decision was the first and most critical step, as the enclosure design had to be fully adapted to the chosen manufacturing method. With FDM, the cost difference between producing one unit and one hundred units is minimal, making it ideal for short runs and iterative product development.

Design, Prototyping, and Final Result

The enclosure was designed as two main parts, incorporating clips, guides, and mounting points for the electronic components. Small but critical details were also included, such as port openings, antenna placement, and controlled airflow paths for cooling. Given the compact dimensions, design precision was crucial—differences of just a few tenths of a millimeter could cause serious assembly issues.

The project went through multiple iterations, with each new version printed, tested, and refined. The ability to rapidly produce prototypes allowed us to reach an optimal solution without significant cost increases. The final result was a compact, functional, and carefully engineered enclosure that fully met the original requirements.

Thanks to 3D printing, the product was developed quickly and at a low cost, while retaining flexibility for future modifications and upgrades. This type of manufacturing proved to be the most efficient solution for short production runs and early-stage hardware products.