Context and Challenge

The Mercedes-Benz W124 has long crossed the line from “used car” into the realm of a true classic with steadily increasing collector value. For owners and enthusiasts, an authentic interior is just as important as mechanical condition. Over time, however, even well-manufactured interior components degrade due to material aging.

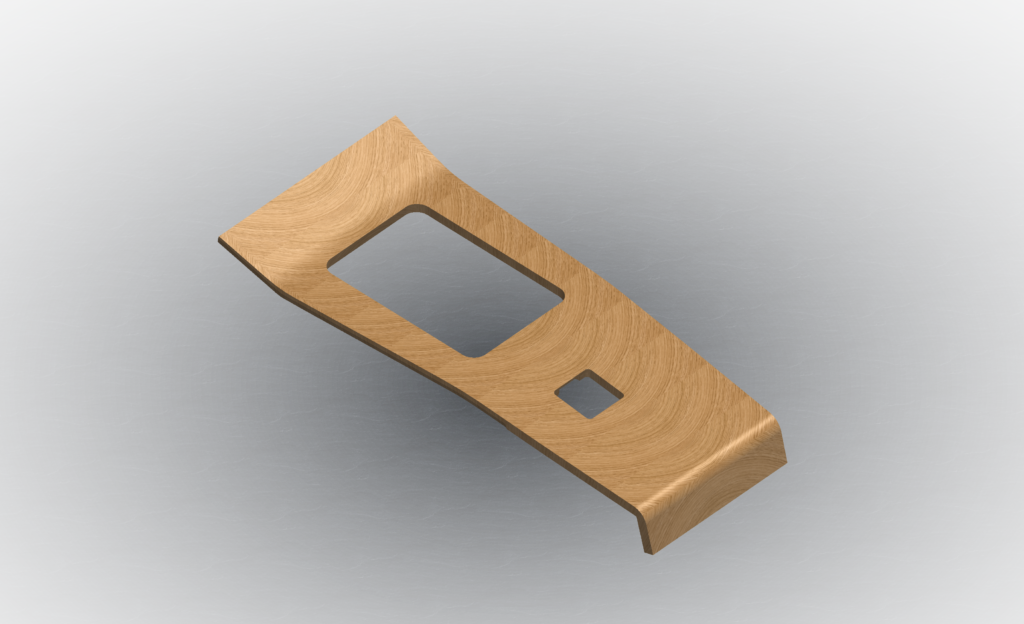

One component,with such problems, is the shifter cover in the center console—a part that may appear simple at first glance, yet plays a critical role in the overall look and feel of a finished interior.

Original W124 shifter covers are now extremely difficult to find, and when available, they are often in poor condition: cracked surfaces, broken mounting clips, and distorted geometry. Existing aftermarket replicas frequently fail to match the original factory geometry, color, or material quality.

The client approached us with a clear objective: to restore the shifter cover with original-level accuracy, while also enabling customization to meet personal requirements—in this case, removing one opening and adding new button positions.

3D Scanning, CAD Reconstruction, and Client-Driven Customization

The project began with high-precision 3D scanning of the original shifter cover. This allowed us to capture all contours, mounting features, and transitions which are essential for proper integration in the vehicle interior.

The resulting point cloud was used to build a clean CAD model, eliminating all deformations caused by decades of use. This stage required a couple iterations, as the original part had warped over time despite being manufactured from durable plywood-based material.

Once the original geometry was fully restored, we moved on to customization. At the client’s request, both structural and visual modifications were introduced to improve ergonomics, aesthetics, and compatibility with other interior elements. This phase highlights one of the greatest advantages of digital engineering—rapid iteration, testing of multiple design variants, and full alignment with individual preferences.

The CAD model was then optimized specifically for FDM 3D printing, taking into account print orientation, operational loads, and long-term structural integrity. While alternative manufacturing technologies were possible, they would have significantly increased cost without added functional benefit. The final printed part proved not only visually accurate but fully functional and robust for everyday use.

FDM 3D Printing Production and Client Value

We have used FDM 3D printing with ABS material, selected for its excellent mechanical strength, wear resistance, and long-term stability. Printing was performed on an enclosed active chamber industrial 3D printer, ensuring proper thermal control and dimensional is stability—essential for durable interior automotive components.

The final surface finish was completed by a team of professional automotive painters specializing in interior trim components, achieving an appearance consistent with factory standards.

A key advantage of this workflow is the preservation of the digital CAD model. This means the shifter cover can be reproduced, further modified, or adapted for another interior variant at any time—without the need for additional scanning or complex setup.

Key Benefits for the Client

- Perfectly fitting interior component for Mercedes-Benz W124;

- Customization options unavailable with factory or aftermarket parts;

- Fast and cost-effective production without compromising quality;

- Extended service life and increased vehicle value.

ТThis case study is a clear example of how the synergy between 3D scanning, CAD engineering, and FDM 3D printing can bring abandoned and obsolete automotive components back to life.

For classic car owners, this approach offers something invaluable: freedom—the freedom to restore, improve, and personalize their vehicles without the limitations of outdated catalogs or unavailable spare parts. And just as importantly, the joy of seeing the interior restored to a condition worthy of a 1990s showroom brochure.