Preserving Design Identity Through Precision CAD and Manufacturing

This case study presents the reverse engineering and reconstruction of the headlight cover (Lights Cover) for the classic NSU TT, a historically significant vehicle often regarded as a predecessor to the modern Audi TT. Although production of the NSU TT ended in 1972, the model continues to be restored and maintained by dedicated collectors and automotive enthusiasts worldwide.

One of the main challenges in restoring classic vehicles is the lack of original spare parts. The headlight cover is a small but visually critical component that defines the front-end identity of the NSU TT. Any deviation in geometry, curvature, or surface detail immediately affects the authenticity of the restoration.

The client’s objective was clear:

to create a fully accurate, functional replica of the original NSU TT headlight cover — without visible deviations, without stylistic compromise, and with manufacturing methods consistent with the original era.

Challenge: Recreating a Legacy Automotive Component

The task required more than simple duplication. The original component showed age-related deformations caused by time, environmental exposure, and mechanical stress. A direct copy would have transferred these imperfections into the new part.

The challenge was to:

- Restore the original geometry, not the aged one;

- Preserve the design lines and visual identity of the 1970s original;

- Ensure manufacturing feasibility for small production series.

This demanded a combination of reverse engineering, CAD reconstruction, and production-oriented design.

Reverse Engineering Process: 3D Scanning and CAD Reconstruction

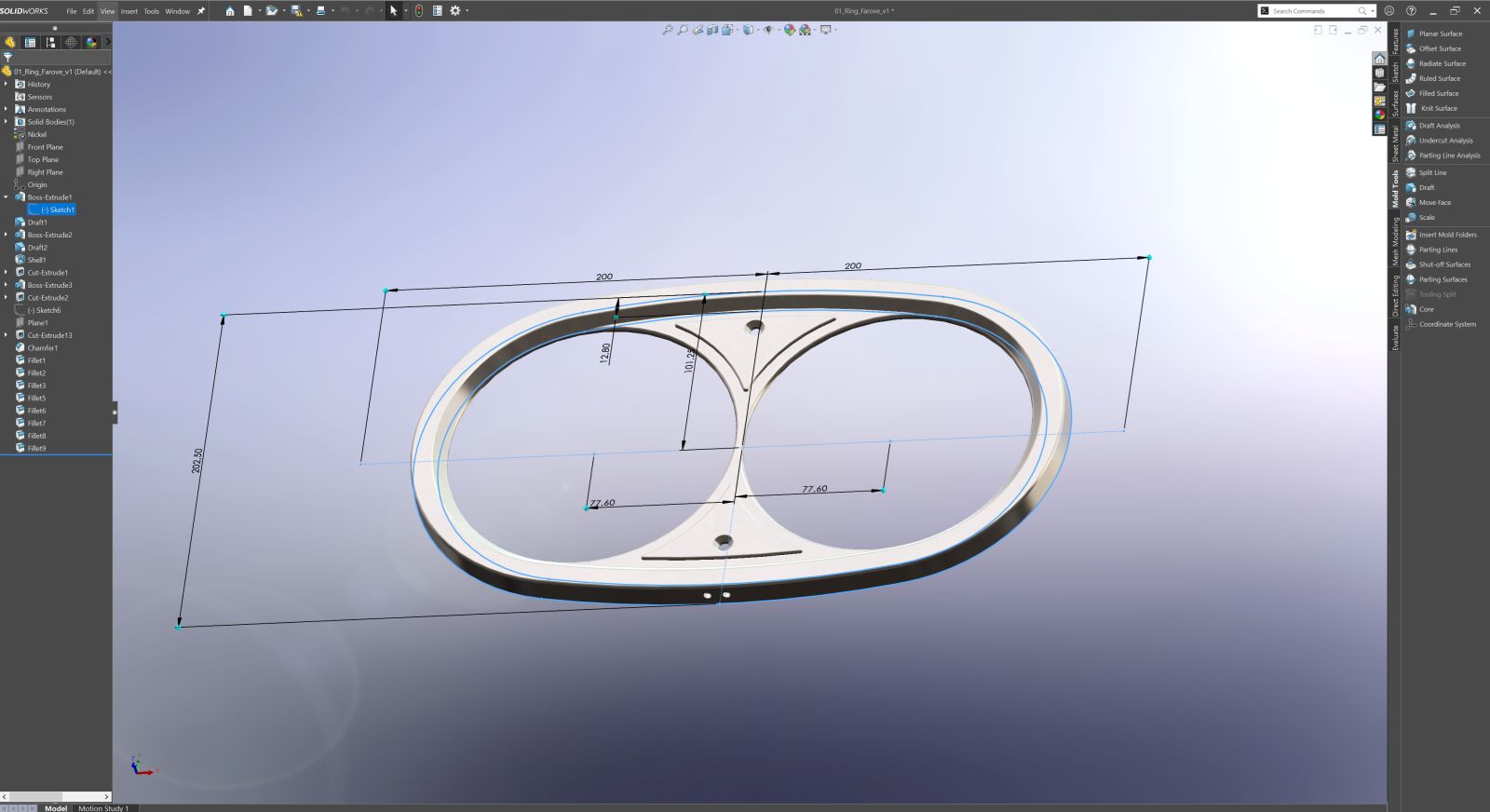

The project began with high-resolution 3D scanning, capturing the complex freeform geometry of the original part with sub-millimeter accuracy. While the component appears simple at first glance, its design includes subtle curves, small radii, and a distinctive edge profile — all essential to the NSU TT’s visual character.

Key steps:

- Processing and analysis of the point cloud data;

- Identification and correction of age-related distortions;

- Reconstruction of the original intended geometry;

- Creation of a clean, fully parametric 3D CAD solid model.

Rather than relying directly on the scan mesh, the geometry was re-engineered to match how the part would have appeared when originally manufactured in the early 1970s.

The resulting CAD model serves both as:

- a manufacturing-ready reference, and

- a digital archive, enabling future production runs or use by restoration communities and automotive clubs.

Manufacturing Strategy: Tooling and Forming Method

Given the visual and functional importance of the headlight cover, mechanical forming using punch and die tooling was selected as the optimal production method.

This approach ensures:

- High dimensional accuracy;

- Excellent repeatability between parts;

- Structural stability during installation;

- Perfect alignment with original mounting points and body curvature.

To support this process, a custom aluminum forming tool (punch and die set) was designed and manufactured specifically for this project. The tooling was tested, calibrated, and refined to achieve exact conformity with the original NSU TT design lines.

Validation, Production, and Results

Following tooling completion, a series of test parts was produced. Each component underwent dimensional and visual inspection, comparing:

- manufactured parts vs. CAD model;

- manufactured parts vs. original component.

This validation included post-production 3D scanning and deviation analysis.

Final outcome:

- Accurate reproduction of geometry and proportions;

- Authentic material feel: lightweight, rigid, and visually correct;

- Manufacturing-ready component suitable for small series production;

- Value Delivered to the Client.

The project provided several key benefits:

- Full authenticity – visually and functionally indistinguishable from the original 1970s component;

- Repeatable production capability – CAD data and tooling enable future batches;

- Support for restoration communities – availability of factory-accurate replacement parts;

- Increased vehicle value – critical design element restored to original specifications.

This case demonstrates how reverse engineering combined with modern CAD systems and traditional manufacturing techniques can bring historically significant automotive components back to life.

For vehicles like the NSU TT, every restored contour and design line contributes to preserving true engineering heritage. Accurate reconstruction is not just replication — it is engineering preservation.