Personalization is increasingly becoming a key factor in creating products with real added value. In a landscape dominated by mass production, custom design clearly differentiates an object and gives it meaning beyond pure functionality. Additive manufacturing makes this individuality economically worth — even for very small production runs. This balance between engineering logic and freedom in design was the foundation of the following project.

A Product Concept with Individual Character and Limited Production

Creating custom products through 3D printing has always been a core part of our work. This technology enables the development of distinctive, character-driven products at a relatively low unit cost, aimed at a niche audience that values originality and a personal approach. The ability to move beyond the constraints of mass manufacturing makes additive technologies particularly suitable for limited series and special projects.

For this project, a corporate client approached us with a clear objective: a gift for a small group of partners and clients, an authentic object with genuine practical value. The requirement was for the gift to avoid the look and feel of a standard promotional item and to be unavailable on mass-market platforms. The concept was a mini stereo Bluetooth receiver, designed for office use, with options for corporate branding and personalization featuring the recipient’s name. The planned production run was approximately 20 units.

Engineering Component Selection and Acoustic Design

The project began with the selection of electronic components. The main challenge was choosing a suitable amplifier and speakers that met both the dimensional constraints and the predefined budget. The option of integrating a battery was considered, but it would have increased the overall size and compromised compactness. As a result, the decision was made to design the device without an autonomous power supply.

Once the electronics were finalized, attention shifted to acoustic performance. The internal geometry of the enclosure was carefully designed to improve sound distribution and achieve deeper bass despite the limited internal volume. Testing confirmed that even at this scale, the device delivers a full, well-balanced sound—perfectly suited for an office environment.

Design, Manufacturing, and Final Result

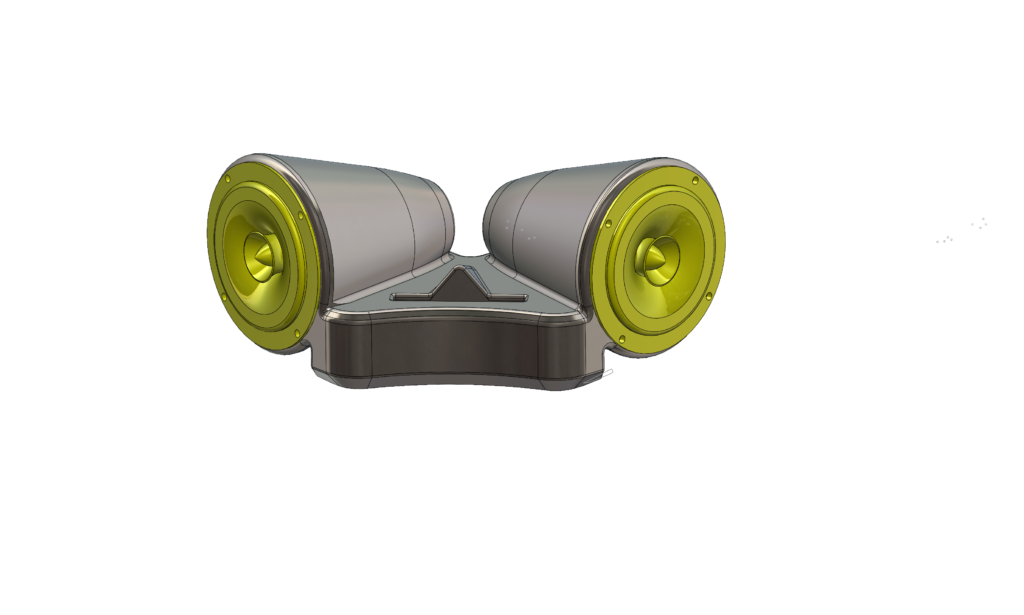

After several design iterations, the final construction consisted of four main components: a base that houses the amplifier board, a cover fixed to the base with screws and two identical conical speaker enclosures bonded to the cover.

The design also includes an integrated phone stand, allowing users not only to listen to music but also to watch video content with true stereo sound. Separate soft TPU feet were 3D printed to minimize vibration transfer to the surface.

The logo and the recipient’s name were produced using resin printing and painted prior to final assembly. At the client’s request, the device was designed without buttons, rotary controls, or light indicators. This resulted in a clean, brutalist visual language, giving the product the appearance of a solid, monolithic object.

Assembly time per unit is approximately 15 minutes. The final result is a compact, functional, and fully personalized product with a distinctive form — a gift that cannot be purchased off the shelf, but only created with intent. This makes it a strong and meaningful gesture of appreciation toward employees and clients alike.