When a Small Component Has No Substitute

In classic car restoration, there comes a point where compromises are simply not an option. Although some parts may appear interchangeable at first glance, in reality they operate in strict dependency with surrounding components. Any change in material, shape, or geometry can result in installation issues, unwanted vibrations, or long-term reliability problems. This project was a perfect example of such a case.

The component which we are talking about was a special exhaust adapter connecting the engine head exhaust outlet to the exhaust system of a VW Beetle — a car loved for generations for its boxer engine and iconic sound. The client was restoring the engine to a fully authentic shape and had spent a long time searching for this part. New production no longer exists, and finding a used component in acceptable condition is practically impossible.

Attempts to fabricate a substitute using improvised materials proved unsuccessful. Despite its small size—approximately 7 × 7 × 7 cm—the part is critically important. In manufacturing, smaller components often involve significantly higher complexity, and this was no exception.

From a rusty authentic part to an accurate 3D Model

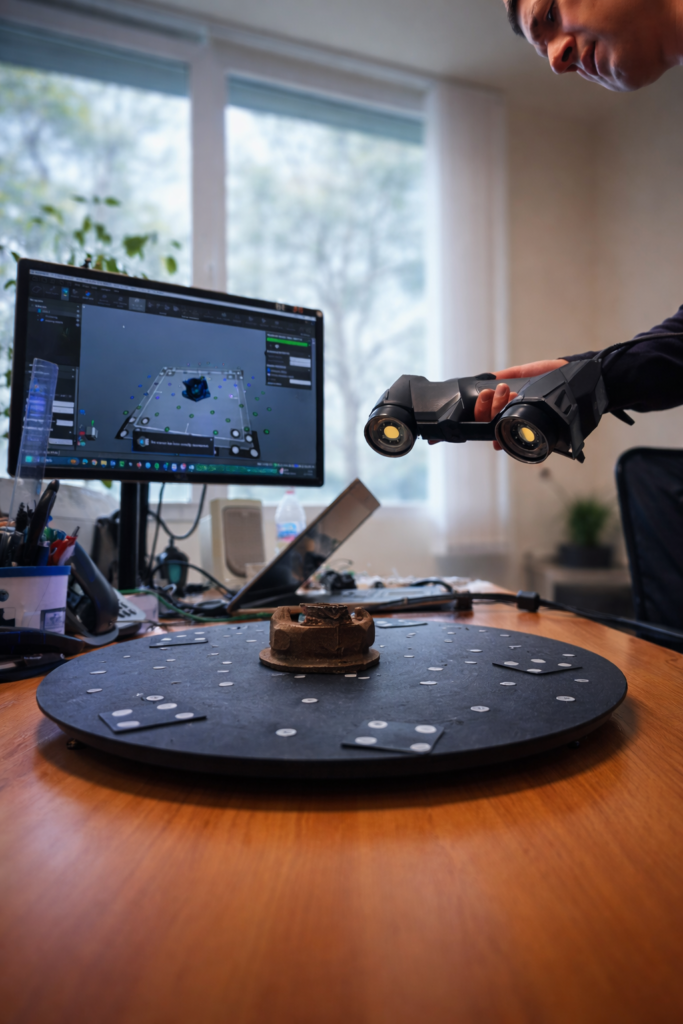

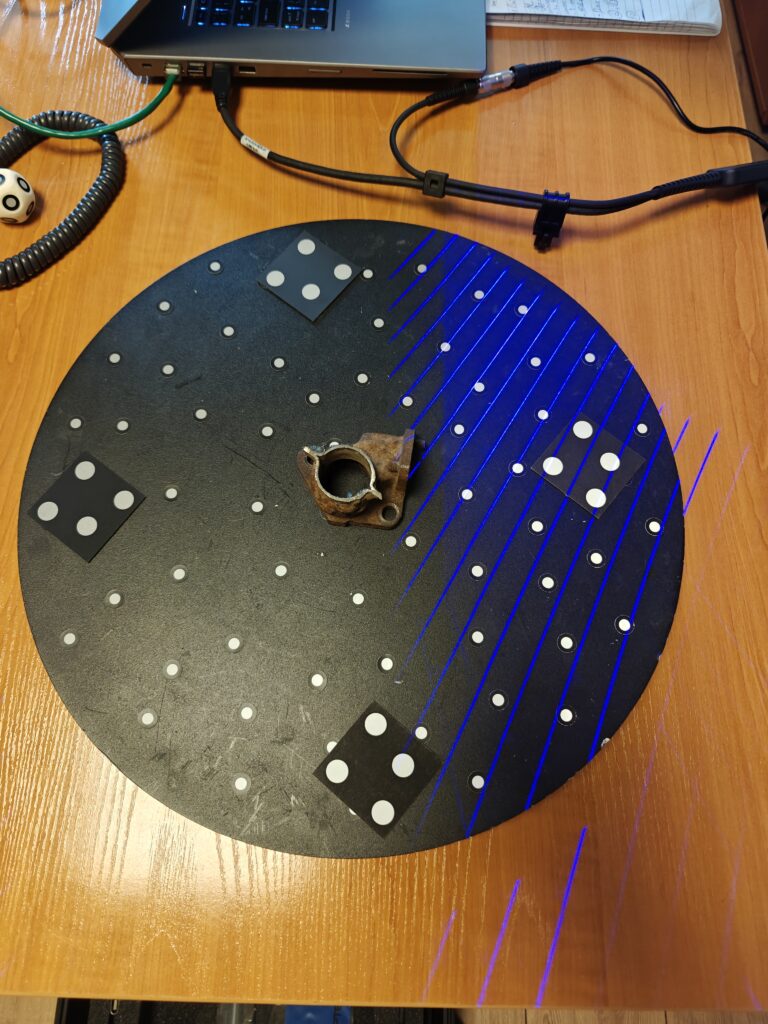

The original component was in poor visual condition, showing corrosion, carbon buildup, and signs of decades of use. Nevertheless, it served as the foundation for high-precision 3D scanning, allowing us to capture its true geometry.

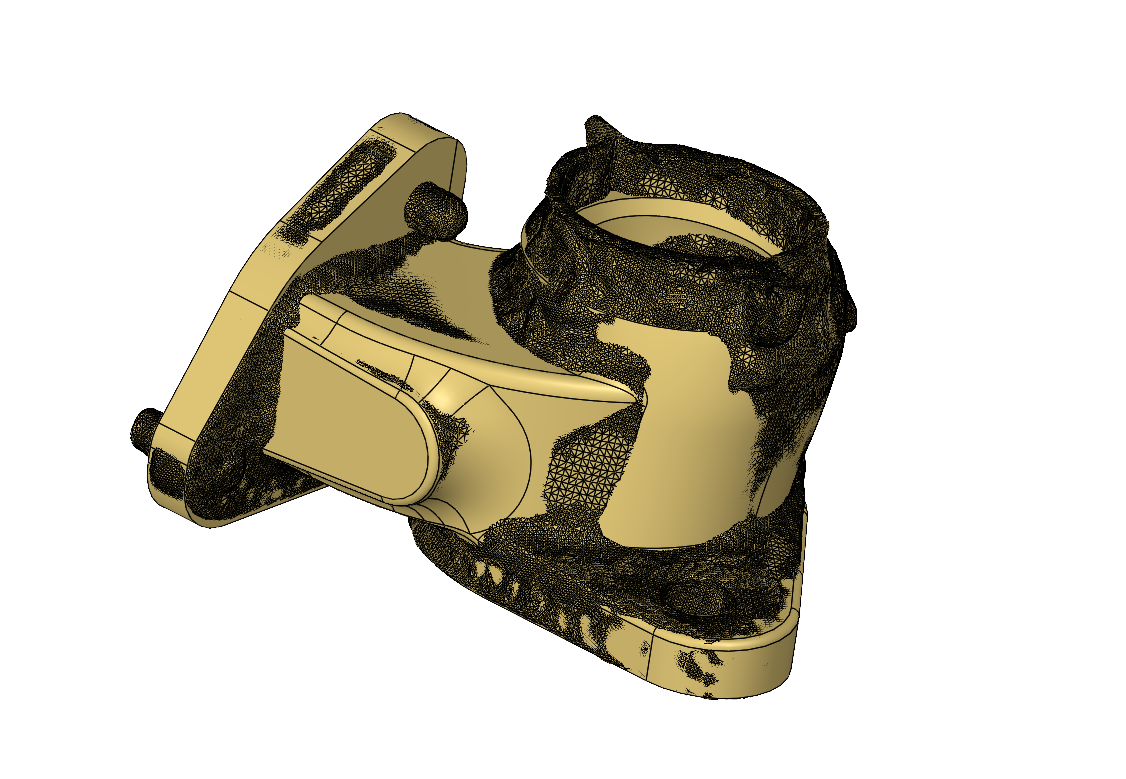

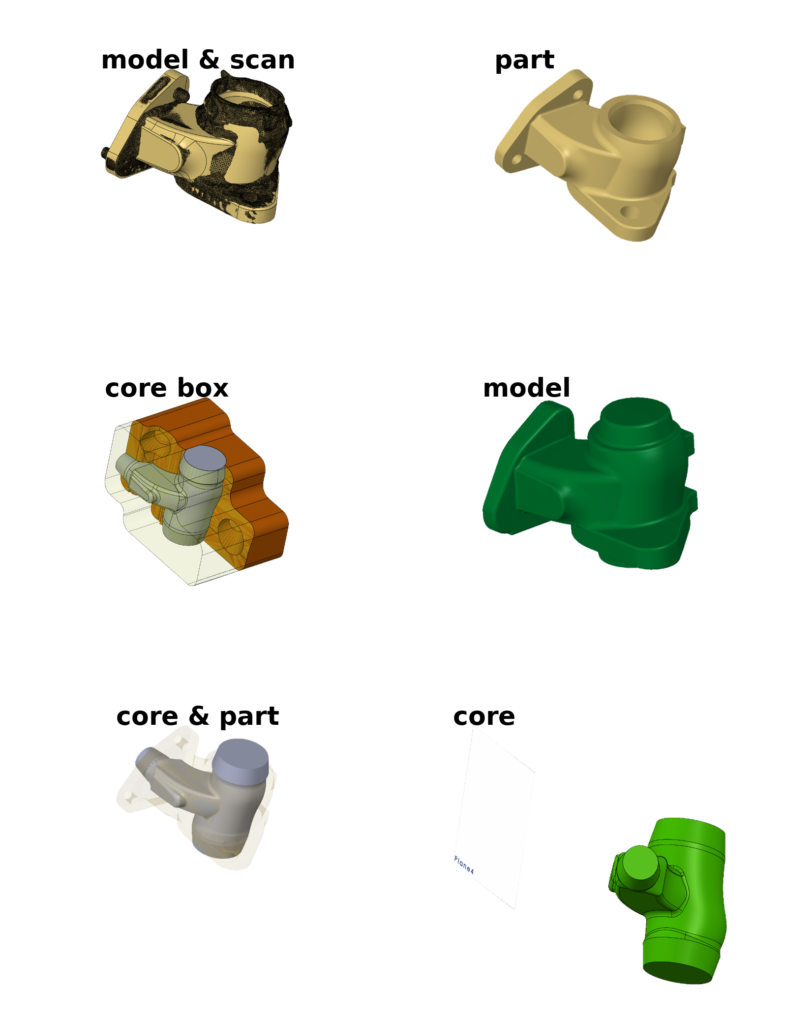

The resulting point cloud was imported into SolidWorks, where a complete solid CAD model was built step by step. During this process, wear-related defects were removed and the geometry was restored to its original design intent.

A detailed comparison between the scanned data and the reconstructed CAD model revealed an exceptionally high level of accuracy, except in the heavily worn areas. This was a critical milestone—any geometric deviation would have caused installation issues or functional problems within the exhaust system. The final CAD model was not merely a visual reconstruction, but a precise engineering foundation for the next and far more complex phase of the project.

Tooling Design for Sand Casting in Grey Cast Iron

Material selection was straightforward: grey cast iron. It is the only material that simultaneously meets all requirements—operation at temperatures up to 700°C, vibration damping, resistance to thermal cycling, and long-term durability. Additionally, grey cast iron offers excellent castability and relatively low production cost, making it suitable even for small series manufacturing.

The core challenge was the design of the casting tooling for sand molds. This included the pattern model and a core box, produced via 3D printing, used to form the internal geometry of the part.

Special attention was paid to the core box design, which was split into two shell halves along a complex and irregular parting line. This approach allowed the core to be removed smoothly after molding. Required draft angles and machining allowances were incorporated into the pattern design, aligned with the chosen parting line. Shrinkage allowances for cast iron and additional material for post-casting machining were also carefully calculated and applied.

Skipping any of these steps would have made it impossible to produce a component that meets the original dimensional and geometric requirements.

Final Result and Impact

The final result is a fully functional exhaust adapter that meets all technical specifications, along with robust tooling that enables repeatable and reliable production. The success of the project was achieved through close collaboration between engineering design, casting, and post-processing machining.

This case clearly demonstrates that by combining 3D scanning, CAD engineering, and modern tooling manufacturing methods, even the rarest and most critical automotive components can be successfully restored—quickly and at a reasonable cost.

For the client, this meant more than just replacing a missing part. It restored the ability for their VW Beetle to operate exactly as originally intended—authentic, reliable, and uncompromised. Following the success of the project, the component was produced in a short production run and made available to other enthusiasts of this iconic vehicle.