Context and Engineering Inspiration

3D printing is no longer an experimental technology—it has become a practical and powerful tool for increasing efficiency across multiple industries, from mechanical and automotive engineering to furniture and interior design. Its greatest advantage lies in design freedom: the ability to create components with complex geometries that would be extremely difficult, slow, or economically unjustifiable to manufacture using conventional methods.

In many cases, a single 3D-printed component can replace several traditional parts, resulting in reduced weight, fewer assemblies, and a significantly lower overall production cost—provided the component is designed correctly and manufactured using the appropriate technology.

This philosophy formed the foundation of the present project: the development of a round extendable dining table, inspired by the legendary Fletcher table. Designed more than a century ago, this ingenious piece of engineering allows a compact round table to seat six people when closed and up to twelve when fully extended. Originally conceived for yachts and ships, it remains an elegant solution for space-constrained environments.

The Challenge: Complex Mechanics and Limited Serial Production

Despite its brilliance, the Fletcher table concept is rarely found in serial production. The reasons are clear: a highly complex mechanism, numerous interdependent components, strict precision requirements, and substantial investment in time and resources. It is a true engineering masterpiece that is extremely difficult to replicate.

While furniture makers have created tables with similar functionality using alternative mechanisms, many manufacturers have been discouraged by the complexity involved—even though the concept has inspired numerous attempts over the years.

The client who approached us had a clearly defined goal: a round, elegant extendable table that is easy to use, reliable, and suitable for 8 to 12 people. An additional and critical requirement was that the design had to be repeatable and scalable, with the potential for future production rather than being a one-off handcrafted solution.

Engineering Design and the Role of 3D Printing

The design process started from scratch and was carried out entirely in SolidWorks. All movements, kinematics, and potential collisions were precisely simulated, allowing the mechanism to be optimized during the design phase and eliminating potential issues before physical production began.

A key decision in the development was to manufacture approximately 30% of all components using 3D printing. This approach significantly simplified the construction, reduced weight, and made assembly easier. Most importantly, it enabled the creation of complex functional components that would have been prohibitively expensive or labor-intensive to produce using CNC machining or casting.

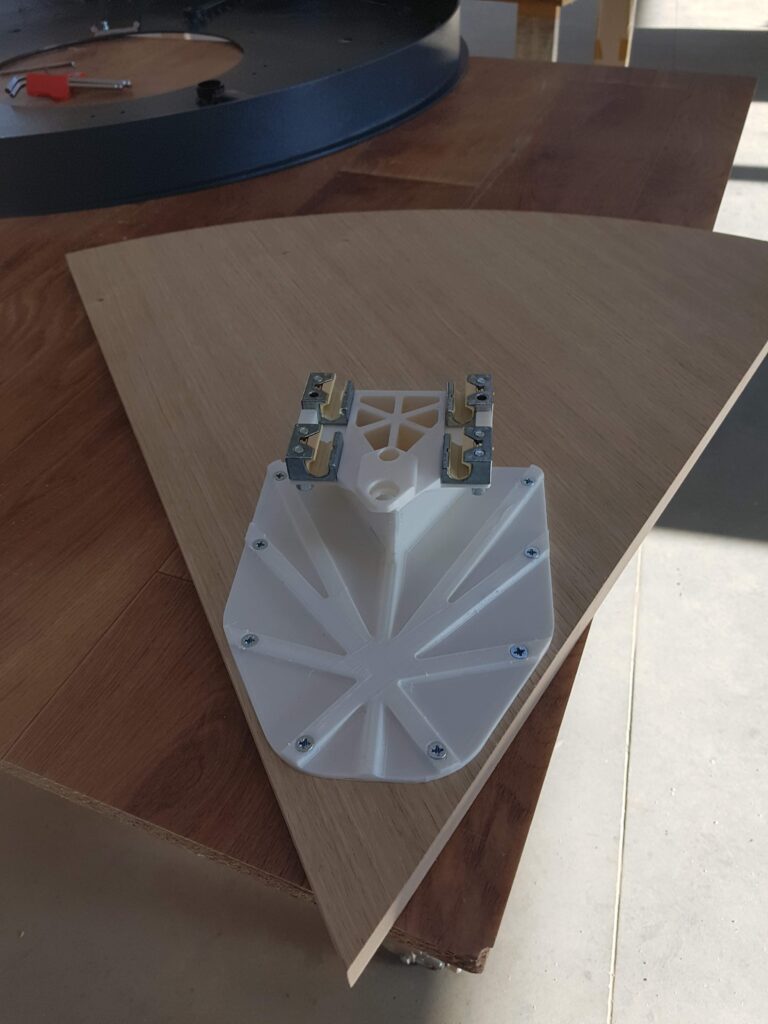

For larger structural components, FDM technology was used with industrial-grade filaments featuring enhanced mechanical properties suitable for highly loaded parts. Smaller and more intricate components were produced using SLS technology with PA12 material, ensuring high dimensional accuracy and strength. For FDM printing, BASF PRO materials were selected for their excellent strength, wear resistance, and thermal stability.

The final design combines 3D-printed components with standard mechanical elements, including aluminum guide rails, radial, roller, and sliding bearings, as well as housings manufactured through laser cutting and welding. CNC-routed MDF elements were also incorporated. The project was developed in close collaboration with professional furniture makers, achieving an optimal balance between reliability, cost efficiency, and aesthetics.

Result and Value for the Client

The final result is a table that seamlessly blends engineering logic, functionality, and refined design. It extends smoothly, assembles relatively easily, and—most importantly—the construction is fully repeatable. This characteristic sets it apart from most similar solutions on the market.

At the client’s request, photographs of the finished product cannot be publicly shared. However, software-generated visualizations accurately represent the final construction, along with selected images from the assembly process. The outcome was highly impressive, and the most important measure of success—a fully satisfied client—was achieved.

This project is a clear example of how 3D printing can be successfully integrated with traditional manufacturing technologies, opening new possibilities for engineering and design solutions that until recently seemed difficult or impossible to achieve. As additive manufacturing technologies continue to evolve, their role in complex, functional products like this one will only grow.